Pick and Carry Crane SLI Solution

Safe Load Indicator for Pick and Carry Cranes – The new generation and the Hydra series are majorly prone to accidents, primarily because their operations are more complex. They move with the load, carry out load using multiple hooks of variable capacity, have articulation function. All these often lead to high chances of accident due to rapid stability loss and toppling of the crane.

Klug Avalon has a deep knowledge and experience in offering solutions to its customers. We have a team of field experts, who constantly keep on innovating to make crane operations safer and productive. One of the major reasons all major OEMs prefer working with us is because we add value to their business.

Klug Avalon specifically designed a system for pick & carry cranes. The system measures the pressure in the luff cylinder to calculate the lifted load. This method helps to calculate the load on all the crane hooks; either fixed or moving. A major advantage of the system is that there is no need for any dead weight for system calibration. The system is self-calibrating.

Enquire For Solution >

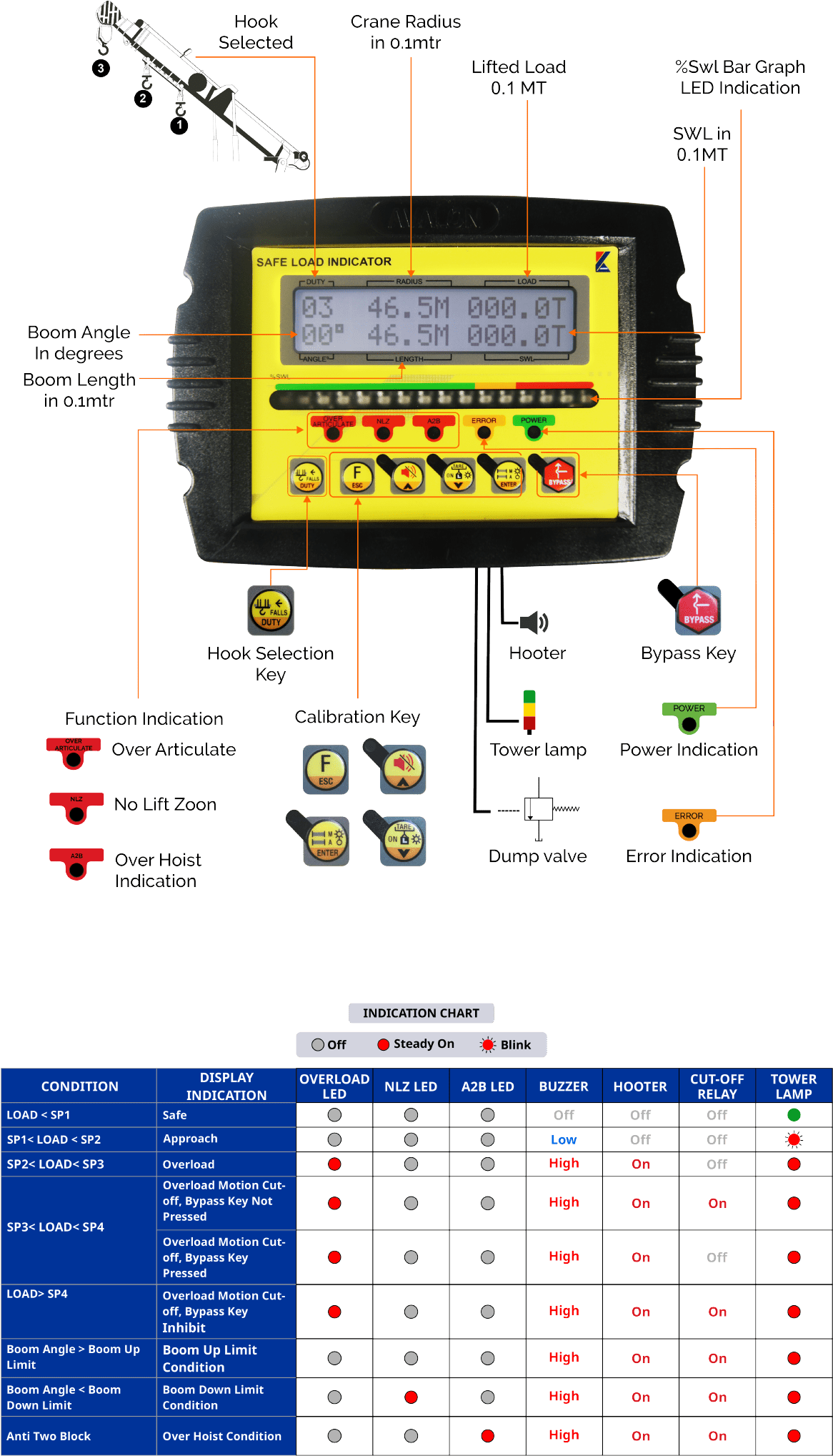

Specifications- Pick and Carry Crane LMI Solution

Pressure sensor measures the luff pressure in lift cylinder. The lifted load is calculated based on the pressure output. This method helps to measure the load lifted by all hooks- fixed or moving.

No welding of load sensor on the crane boom. The three pulley load sensor – dynamometer is an outdated technology that causes damage to the wire rope due to abrasion with the pulley and also it disturbs the winding of the wire rope on the hoist drum.

Auto calibration, the system doesn’t require any weights at the site for calibration. Saves headache and cost involved in arranging the weights at the site.

Sunlight readable backlit LCD display, UV stabilized with antiglare coating

Clear & easy to understand audio & visual annunciation for exceptional conditions

Simple, easy to do wiring using waterproof connectors

Output available to drive a hydraulic dump valve for implementing motion cut-off function, protecting the crane from an accident.

Robust-built, sealed components designed to operate in rough & rugged conditions. Water ingress protection on all outdoor components.

Easy to use, operator-friendly & trouble-free operation.

Operates on 10v to 30v battery supply

Serial port output to integrate telematics device to transmit lift data to the cloud.

Protection against overloading:

Overloading may cause structural failure, breaking of wire rope may lead to an accident. The KOPS prevents this by monitoring the load lifted by all the hooks and displays it on the display unit. On overload, the systems provide an audible and visual alarm to alert the operator and further activates the cut-off device to stop further movement of the crane in dangerous conditions.

Protection against over hoisting of hook:

For long boom cranes and lifting at full boom length, the crane operator is not able to clearly see the hook block. If the head pulley block collides with the hook block it may cause wire rope breakage leading to an accident. The KOPS system uses an A2B switch with a dead weight suspended to it, to monitor over-hoisting avoiding an accident.

Hook selection-auto roll back:

In a pick n carry crane where there are multiple hooks, the inner most having larger capacity while the outer hook having lower capacity. This facility resets the hook selection to the lowest capacity hook after a lift is complete. This will ensure that if the operator forgets to select the correct hook, he may lift the higher capacity load on the outer hook, while the inner hook is selected.

Safe and selective bypass:

By adding a cut-off function to the standard system, KOPS will auto bypass only the unsafe motion of the crane instead of completely freezing all motions. The operator can operate only those motions which will bring the crane to a safe condition. Thus ensuring complete safety.

Ensuring crane operator does not continue operating the crane when its overload:

The KOPS on overload condition activates a motion cut-off dump valve to stop the crane from further moving in a dangerous condition. The dump valve is connected to the crane hydraulic line. When activated the hydraulic oil is sent to the tank stopping the crane operation. The crane operator then needs to press the bypass key, responsibly to bring the crane to the safe condition by taking corrective action.

Voice alert the surrounding using high pitch hooter and visual alert using a Tower lamp:

As per the international safety standards, the crane surrounding needs to be Annunciated, when the crane is in unsafe condition. This is for alerting personnel working close to the crane so as they could move away from the vicinity of the crane.

Protection against toppling due to over articulation:

Lifting of load when the crane is articulating may cause a rapid loss of stability resulting in the toppling of the crane. The KOPS system de-rates the crane capacity during articulation and helps prevent toppling.

Fail safe:

This function of KOPS, when configured by the supervisor, will ensure that the crane will not operate, if the safety system is bypassed or not functional. This ensures full safety at site.

User settable set-points:

The KOPS system has five programmable set points. Based upon the % SWL the KOPS activates various alarms, both visual & audible. These set-points can be set by the user (through password-protected supervisor settings) depending on the site requirements. E.g. Sites, where safety is much needed like a petrochemical plant/ nuclear plan the set-points %value can be reduced to make crane operation safer.

Protection against load lifting when the boom angle is in No Lift Zone (NLZ):

The load chart provided by the crane manufacture mentions the working boom angle for lifting the load. For lower boom angles the load chart specifies no lifting of any load to avoid toppling of the crane. The KOPS monitors the boom angle and annunciates the operator with a distinct audible and visual alarm preventing an accident.

Ensuring the bypass function is not misused by the crane operator:

When in an overload condition, if the operator misuses the bypass key to operate the crane (instead of taking corrective action to bring the crane to safe condition), then a bypass inhibit function proves very helpful. The KOPS has a fifth set-point, wherein if the % SWL crosses the set-point 5 it will freeze all crane functions, and even pressing the bypass key won’t help. The operator then needs to contact the crane supervisor for help. The crane supervisor using his password can ask him to get the crane in a safe condition. This facility proves very useful in avoiding an accident.

We keep on adding many more safety features to our system periodically. For more information please contact our sales team.

Connect

Logger

Enabled

Tracking

Solutions – Casestudy

SLI System for Pick & Carry Crane

A2B Switch

A2B Switch

KOPS Digital Display

Length Angle Sensor

Length Angle Sensor

Pressure Sensor

Other Crane Safety Solutions

Telescopic Crane

Lattice Boom Crane

Tower Crane

lorry Loader Crane

View All Solutions

Hands-on

Training

Pick & Carry Crane Solution

Connect to Our Crane Safety Expert

Download the Broucher!

On-Site Environment

Together

Services

What is Safe Load Indicator?

Safe Load Indicator is a safety control unit mounted in the crane’s cabin to alert the operator if the lifted load is against the Crane Rated capacity. Roughly depends upon other factors too i.e. Correct Boom Angle, Selection of correct Hook, Boom Length, Wind Speed, etc.

Load Moment Indicator does the job of finding unsafe lift motion of the crane and alerting the operator not to further proceed with the lift movement. This Crane Safety System is a must factor for all types of Crane.

Is it necessary to install Safe Load Indicator in Pick and Carry Crane?

Yes, it’s necessary and important to avoid any future accidents while working with materials without knowing the actual load and rated crane capacity.

Send your crane make-model and load chart to sales@klugavalon.com

What if we have old crane dose your SLI system support our crane operation?

Yes off course, as per your crane capacity chart we will make a custom SLI system that matches your crane and its operation

We have pre-installed SLI system, still its need to update?

Yes, sometimes pre-fitted safety systems are inadequate to protect hence we recommend to talk our crane safety system officer and knowing the best-suited solution for your crane.

What is Safe Load Indicator price for pick n Carry Hydra Crane?

Safe Load indicator price purely depends upon the crane’s make-model and load chart, Some cranes have pre-installed safety systems (which are inadequate to protect the crane as full protection) and required additional safety. Based on the final prices will be defined.

Call our Crane Safety Engineer in your Area/region and get your Quotation for Safe Load Indicator