Sensing

opportunities

for you

We work with an eye on the future. We don’t just evolve with the times; we anticipate needs and stay ahead of the curve in a dynamically changing world.

Founded in the year 2000, Klug Avalon is backed by two+ decades of experience in material-handling safety products. Our expertise enables our customers to provide safe working conditions in challenging material-handling environments.

Commitment to quality, deep market insights and a state-of-the-art manufacturing facility help us deliver products that proactively help our customers to sense new opportunities for growth.

Mission

We exist to sense every opportunity for our customers and sensitise them to its potential of maximising safety, profits and reputation for their business.

Vision

To establish a prominent global presence by providing intelligent inputs with forward-thinking mechatronics solutions that help our customers stay ahead of the curve.

Crane safety

products

Klug Avalon’s crane safety products (SLI / LMI / RCI) enable safe load-lifting operations in the construction, marine and factory segments. They are tailor-made products customised as per the type of crane. They monitor critical load-lifting parameters of cranes to eliminate judgemental errors and accidents.

High-precision

Klug Avalon LMI/SLI/RCI products are designed to achieve precision in the harshest of outdoor environments. They can sustain dynamic and shock-loading pressures to deliver accurate results and long service life in rugged conditions.

Easy to use

Our products are easy to use and operator-friendly to install and calibrate. In most cases, they can be installed without any specific tools. They can be calibrated without dead weights. Cabling is easy with plug-and-play connectors. Error codes are provided for fault diagnosis.

Powered by data

Our solutions are powered by a mobile app that enables:

- Bluetooth connection between mobile phone & SLI/LMI/RCI data.

- Data transfer to the Cloud.

- Data logger technology for storage.

- GPS tracking & geofencing.

- IoT.

Fast delivery

An integrated manufacturing facility and a high level of automation enable us to keep our lead times very low.

Design &

manufacturing

Design rules the future

Design is the brain behind precision and quality. Our design department is fortunate to have a highly qualified and creative team that believes in competing with itself to achieve greater innovation and finesse in product designs. Our in-house customized designing software lends a high level of precision to our products.

Integrated manufacturing

Spread over 10,000 sq. meters, our manufacturing facility in Pune, India, facilitates an integrated, streamlined, end-to-end production process. This gives us absolute control of quality, timelines and customisation of products. Our lead times range in days and are among the industry’s shortest.

Manufacturing encompasses the PCB production department, mechanical engineering department, quality testing unit and the packaging section.

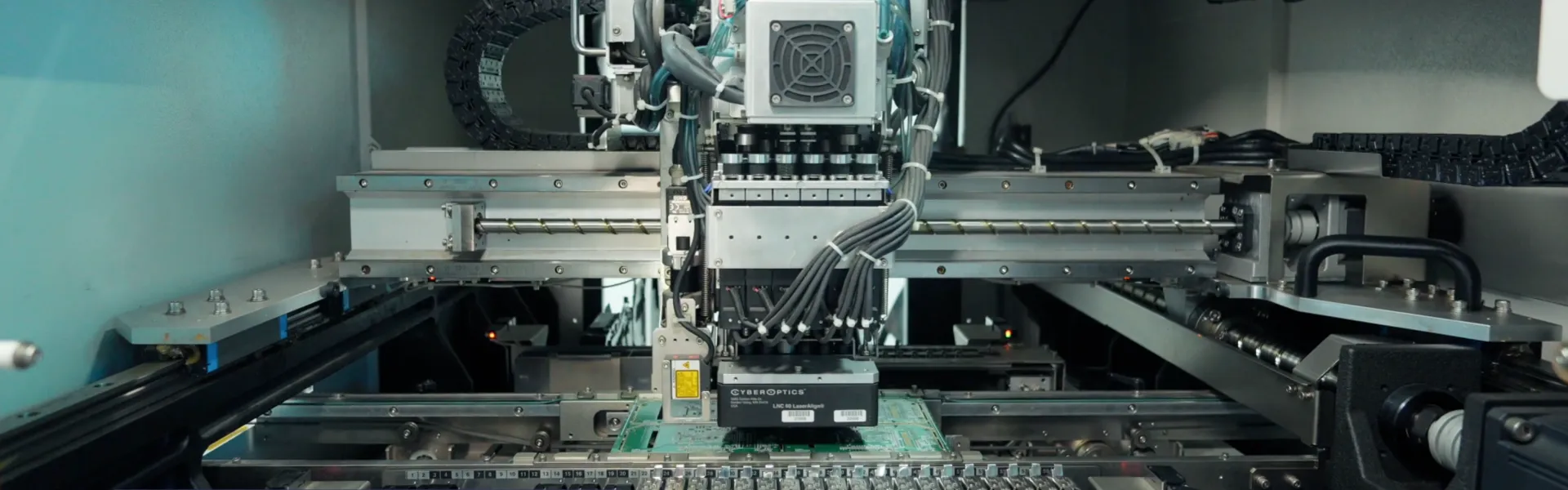

The PCB assembly line

The PCB assembly line achieves end-to-end production of PCBs required for sensors, LCD displays and LED displays. Its assemblage includes laminar clean rooms, reflow ovens, AOI, and pick-n-place machines.

The mechanical engineering department

The mechanical engineering department is well-equipped with VMC, CNC, MMN and laser welding machines for metal and plastic component manufacturing. Moulding is done in-house, allowing us to customise shapes and sizes per customer requirements.

A high level of automation

A high level of automation in manufacturing has facilitated unprecedented precision and efficiency in the development and production of software, PCBs and mechanical components. Additionally, systems such as SAP, Kardex retrieval system, etc., have enhanced the efficacy of production. Further, our proactive adoption of emerging technologies like CANBUS has ensured swifter inter-process communication.

Customisation

Customisation is a major advantage that comes with end-to-end manufacturing capabilities. From customised shapes and sizes of products to customised UIs and multi-lingual annunciations, we are able to offer uniquely branded products to our customers.

A green policy

A green policy is a part of our manufacturing activity. It focuses on waste reduction and green energy. We have incorporated burnout chambers to manage the combustible organic factor in solid waste. We also invest vigorously in solar energy.

Comprehensive

in-house testing

A comprehensive in-house testing infrastructure helps us to work towards a zero-defect policy. We have automated facilities for temperature, rain and green testing. Testing machinery includes ESS machines, rain-chamber, and cyclical temperature chamber. ESD and EMI testing for emissions and immunity are also done in-house.

A highly skilled

workforce

Twenty-four years of experience has helped us build a dedicated team of highly trained and skilled workforce adept at handling sophisticated machinery and accomplishing niche jobs requiring domain-specific human skills. A case in point is load-cell manufacturing, where a devoted team of twelve highly skilled and trained workers ensures precision and quality.